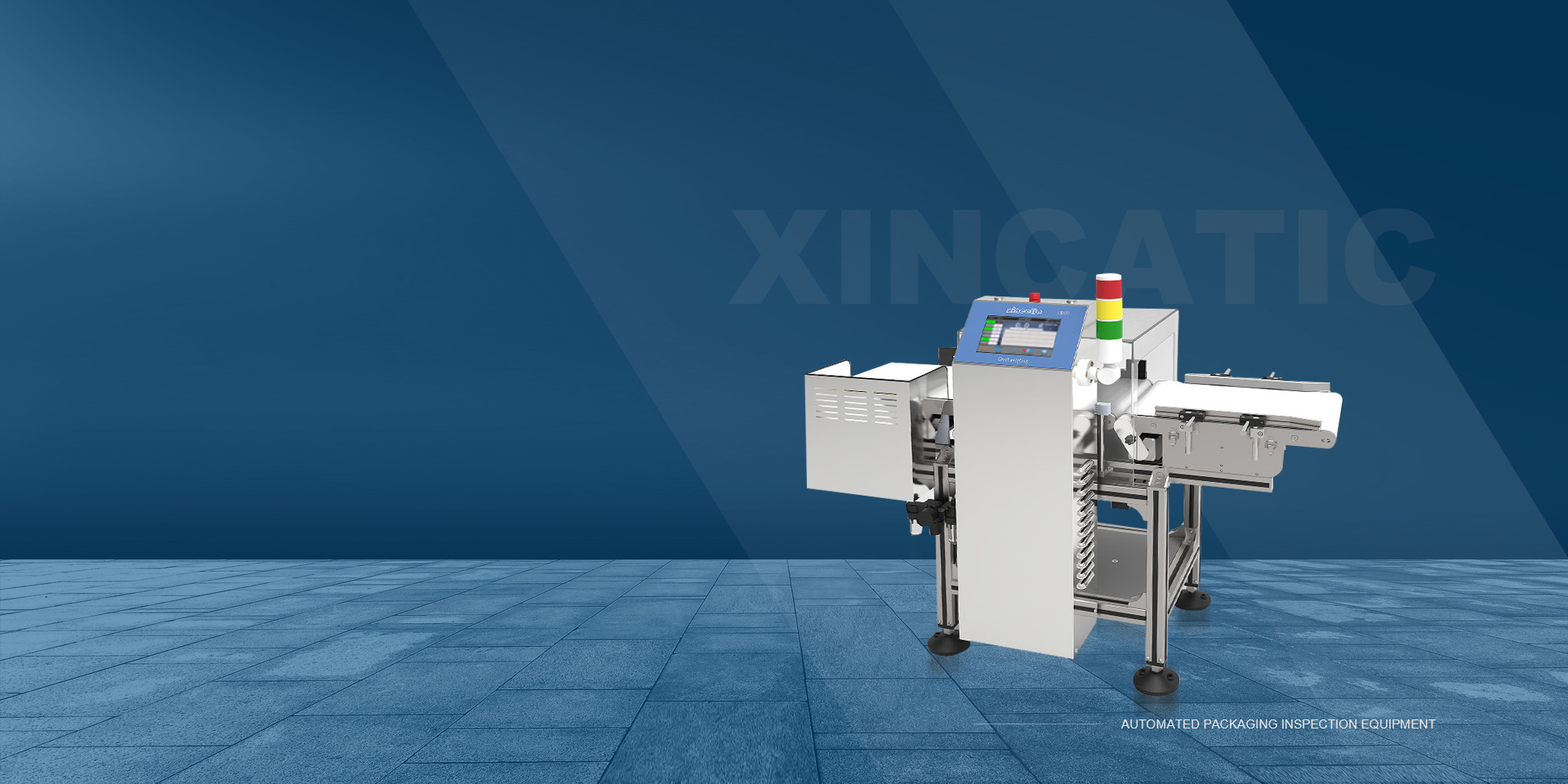

Supplier of production automation packaging testing equipment !

Tel: 0086-20-82516791 | E-mail: xincatic_james@qq.com

-

-

-

-

Contact

14 YEARS

Focus on achieving excellence

A high-tech enterprise that integrates research, production, and sales, specializing in the production of automated packaging and testing equipment.

MORE +OUR PRODUCTS

Checkweigher And Steel Belt

Who Are We?

Guangzhou Xincatic Electromechanical Equipment Co., Ltd.

Guangzhou Xinzhonghang Electromechanical Equipment Co., Ltd. is a high-tech enterprise integrating scientific research, production and sales, specializing in the production of automatic packaging testing equipment.

Since its establishment in 2009, the company has developed high-precision checkweighers, ultra-high-speed checkweighers, dynamic and static Checkweighers, special checkweighers for bottling lines, large-scale checkweighers, multi-stage sorting checkweighers, multi-channel checkweighers, dynamic and static checkweighers and other online automatic testing equipment, multi-station screening machines, etc. A number of series of products, and has obtained a number of national patents.

Production experience

Company area

Annual production

Company's product

News Center

# Introduction In today's rapidly evolving industrial landscape, the demand for precision weighing solutions has never been higher. Belt checkweighers have emerged as a vital tool for ensuring accuracy and efficiency in production processes. As we look towards the future, it's essential to stay informed about the latest trends and innovations in weighing technology. ## The Evolution of Belt Checkw

Belt checkweighers are an essential component in the field of weighing scales for instrumentation. These specialized devices are used to accurately measure the weight of products as they move along a conveyor belt. By incorporating a belt checkweigher into the production process, businesses can ensure that their products meet specific weight requirements and quality standards. One key feature of b

Enhancing Efficiency with Static Checkweighers in the Weighing Instrument Industry

Static checkweighers play a crucial role in the weighing instrument industry, offering precise and efficient solutions for quality control and product inspection. These advanced devices are designed to accurately measure the weight of items on a stationary conveyor belt, ensuring compliance with weight regulations and standards. In recent research studies, static checkweighers have been shown to s

View More →Online Message

Copyright ©2023 Guangzhou Xincatic Electromechanical Equipment Co., Ltd. |

| Business license | SEO